POWER STEERING:

Showing posts with label Machine Parts. Show all posts

Showing posts with label Machine Parts. Show all posts

Tuesday, December 31, 2013

POWER STEERING

Labels:

Information,

Machine Parts,

Mechanical Creativity,

Technology

Wednesday, December 4, 2013

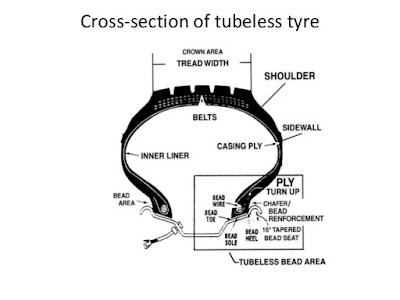

Tubeless tires

Tubeless tires :

Tubeless tires or tyres (in some Commonwealth Nations) are pneumatic tires that do not require a separate inner tube.

Unlike traditional pneumatic tires which use a separate inner tube, tubeless tires have continuous ribs molded integrally into the bead of the tire so that they are forced by the pressure of the air inside the tire to seal with the flanges of the metal rim of the wheel.

Tubeless tires or tyres (in some Commonwealth Nations) are pneumatic tires that do not require a separate inner tube.

Unlike traditional pneumatic tires which use a separate inner tube, tubeless tires have continuous ribs molded integrally into the bead of the tire so that they are forced by the pressure of the air inside the tire to seal with the flanges of the metal rim of the wheel.

Monday, December 2, 2013

An Actuator

An

actuator is a type of motor for moving or controlling a mechanism or

system. It is operated by a source of energy, typically electric

current, hydraulic fluid pressure, or pneumatic pressure, and converts

that energy into motion. An actuator is

the mechanism by which a control system acts upon an environment. The

control system can be simple (a fixed mechanical or electronic system),

software-based (e.g. a printer driver, robot control system), or a human

or other agent.

Sunday, December 1, 2013

Carburetor

Carburetor:-

A carburetor or carburettor is a device

that blends air and fuel for an internal combustion engine. It is

sometimes, but not always, shortened to "Carb" in North America and the

United Kingdom. The carburetor works on Bernoulli's

principle: the faster air moves, the lower its static pressure, and the

higher its dynamic pressure. The throttle (accelerator) linkage does

not directly control the flow of liquid fuel. Instead, it actuates

carburetor mechanisms which meter the flow of air being pulled into the

engine. The speed of this flow, and therefore its pressure, determines

the amount of fuel drawn into the airstream. When carburetors are used

in aircraft with piston engines, special designs and features are needed

to prevent fuel starvation during inverted flight. Later engines used

an early form of fuel injection known as a "pressure carburetor".

that blends air and fuel for an internal combustion engine. It is

sometimes, but not always, shortened to "Carb" in North America and the

United Kingdom. The carburetor works on Bernoulli's

principle: the faster air moves, the lower its static pressure, and the

higher its dynamic pressure. The throttle (accelerator) linkage does

not directly control the flow of liquid fuel. Instead, it actuates

carburetor mechanisms which meter the flow of air being pulled into the

engine. The speed of this flow, and therefore its pressure, determines

the amount of fuel drawn into the airstream. When carburetors are used

in aircraft with piston engines, special designs and features are needed

to prevent fuel starvation during inverted flight. Later engines used

an early form of fuel injection known as a "pressure carburetor".

A carburetor or carburettor is a device

that blends air and fuel for an internal combustion engine. It is

sometimes, but not always, shortened to "Carb" in North America and the

United Kingdom. The carburetor works on Bernoulli's

principle: the faster air moves, the lower its static pressure, and the

higher its dynamic pressure. The throttle (accelerator) linkage does

not directly control the flow of liquid fuel. Instead, it actuates

carburetor mechanisms which meter the flow of air being pulled into the

engine. The speed of this flow, and therefore its pressure, determines

the amount of fuel drawn into the airstream. When carburetors are used

in aircraft with piston engines, special designs and features are needed

to prevent fuel starvation during inverted flight. Later engines used

an early form of fuel injection known as a "pressure carburetor".

that blends air and fuel for an internal combustion engine. It is

sometimes, but not always, shortened to "Carb" in North America and the

United Kingdom. The carburetor works on Bernoulli's

principle: the faster air moves, the lower its static pressure, and the

higher its dynamic pressure. The throttle (accelerator) linkage does

not directly control the flow of liquid fuel. Instead, it actuates

carburetor mechanisms which meter the flow of air being pulled into the

engine. The speed of this flow, and therefore its pressure, determines

the amount of fuel drawn into the airstream. When carburetors are used

in aircraft with piston engines, special designs and features are needed

to prevent fuel starvation during inverted flight. Later engines used

an early form of fuel injection known as a "pressure carburetor".A piston ring

A

piston ring is a split ring that fits into a groove on the outer

diameter of a piston in a reciprocating engine such as an internal

combustion engine or steam engine.

The three main functions of piston rings in reciprocating engines are :

>Sealing the combustion chamber so that there is no transfer of gases from the combustion chamber to the crank.

>Supporting heat transfer from the piston to the cylinder wall.

>Regulating engine oil consumption.

The three main functions of piston rings in reciprocating engines are :

>Sealing the combustion chamber so that there is no transfer of gases from the combustion chamber to the crank.

>Supporting heat transfer from the piston to the cylinder wall.

>Regulating engine oil consumption.

Saturday, November 30, 2013

AIR FILTERS

AIR FILTERS

The air filter is an extremely important part of a car's ignition system. When an engine burns, almost all of the fuel is turned to gas. This gas powers the pistons down, then is ejected from the engine so a new compression cycle can begin. There are many things in the air, however, that don't burn cleanly or at all. If tiny pieces of dirt, road salt, pollen or other contaminants get into your car's air intake, they can damage pistons, clog valves and generally shorten the life of your car. The air filter stops these contaminants from getting in in the first place.

The air filter is an extremely important part of a car's ignition system. When an engine burns, almost all of the fuel is turned to gas. This gas powers the pistons down, then is ejected from the engine so a new compression cycle can begin. There are many things in the air, however, that don't burn cleanly or at all. If tiny pieces of dirt, road salt, pollen or other contaminants get into your car's air intake, they can damage pistons, clog valves and generally shorten the life of your car. The air filter stops these contaminants from getting in in the first place.

The crankshaft

The crankshaft:-

Sometimes abbreviated to crank, is the part of an engine that translates reciprocating linear piston motion into rotation.

To convert the reciprocating motion into rotation, the crankshaft has "crank throws" or "crankpins", additional bearing surfaces whose axis is offset from that of the crank, to which the "big ends" of the connecting rods from each cylinder attach.

It typically connects to a flywheel and to reduce the pulsation characteristic of the four-stroke cycle, and sometimes a torsional or vibrational damper at the opposite end, to reduce the torsional vibrations often caused along the length of the crankshaft by the cylinders farthest from the output end acting on the torsional elasticity of the metal.

Sometimes abbreviated to crank, is the part of an engine that translates reciprocating linear piston motion into rotation.

To convert the reciprocating motion into rotation, the crankshaft has "crank throws" or "crankpins", additional bearing surfaces whose axis is offset from that of the crank, to which the "big ends" of the connecting rods from each cylinder attach.

It typically connects to a flywheel and to reduce the pulsation characteristic of the four-stroke cycle, and sometimes a torsional or vibrational damper at the opposite end, to reduce the torsional vibrations often caused along the length of the crankshaft by the cylinders farthest from the output end acting on the torsional elasticity of the metal.

A poppet valve

A

poppet valve (also called mushroom valve) is a valve typically used to

control the timing and quantity of gas or vapour flow into an engine. It

consists of a hole, usually round or oval, and a tapered plug, usually a

disk shape on the end of a shaft also

called a valve stem. The shaft guides the plug portion by sliding

through a valve guide . In most applications a pressure differential

helps to

seal the valve and in some applications also open it. Poppet valves date from at least the 1770s, when James Watt used them on his beam engines.

seal the valve and in some applications also open it. Poppet valves date from at least the 1770s, when James Watt used them on his beam engines.

Exhaust Resonator

Exhaust Resonator:-

Internal combustion engines usually make a lot of noise while

they are running, and this noise can be annoying and exhaustive

to your ears, especially when it is heard for a long period of time.

Thus, mufflers were created to reduce the noise generated by

the exhaust system. Exhaust resonators, meanwhile, further

reduce the noise by making sound waves that cancel noises

out.

Internal combustion engines usually make a lot of noise while

they are running, and this noise can be annoying and exhaustive

to your ears, especially when it is heard for a long period of time.

Thus, mufflers were created to reduce the noise generated by

the exhaust system. Exhaust resonators, meanwhile, further

reduce the noise by making sound waves that cancel noises

out.

The crankshaft

The crankshaft, sometimes usually

abreviated to crank , is the part of an

engine that translates reciprocating

linear piston motion into rotation. To

convert the reciprocating motion into

rotation, the crankshaft has "crank

throws" or " crankpins", additional

bearing surfaces whose axis is offset

from that of the crank, to which the

"big ends" of the connecting rods

from each cylinder attach.

abreviated to crank , is the part of an

engine that translates reciprocating

linear piston motion into rotation. To

convert the reciprocating motion into

rotation, the crankshaft has "crank

throws" or " crankpins", additional

bearing surfaces whose axis is offset

from that of the crank, to which the

"big ends" of the connecting rods

from each cylinder attach.

Friday, November 29, 2013

Clutch

Clutch, clutch, clutch types, explaining the clutch

Part of Mahrrk parts cars

Clutch (Clutch)

The main purpose of the clutch is reached and the separation of traffic between the engine and the Fund speeds. As he tool to transfer torque from the engine to fund speed gradually to allow the car to move in easily. As he works to separate the movement when changing - interleave - gears or when standing in the case stillness and the engine in motion. clutch is located between the engine and speeds Fund and considered clutch (clutch) is very important in the car.

Part of Mahrrk parts cars

Clutch (Clutch)

The main purpose of the clutch is reached and the separation of traffic between the engine and the Fund speeds. As he tool to transfer torque from the engine to fund speed gradually to allow the car to move in easily. As he works to separate the movement when changing - interleave - gears or when standing in the case stillness and the engine in motion. clutch is located between the engine and speeds Fund and considered clutch (clutch) is very important in the car.

Six-stroke engine

Six-stroke engine

It is a type of internal combustion engine based on the four-stroke engine, but with additional complexity intended to make it more efficient and reduce emissions. Two types of six-stroke engine have been developed since the 1990s.

In the first approach, the engine captures the heat lost from the four-stroke Otto cycle or Diesel cycle and uses it to power an additional power and exhaust stroke of the piston in the same cylinder. Designs use either steam or air as the working fluid for the additional power stroke. The pistons in this type of six-stroke engine go up and down three times for each injection of fuel. There are two power strokes: one with fuel, the other with steam or air.

The second approach to the six-stroke engine uses a second opposed piston in each cylinder that moves at half the cyclical rate of the main piston, thus giving six piston movements per cycle. Functionally, the second piston replaces the valve mechanism of a conventional engine but also increases the compression ratio.

The strokes are depicted as shown below.

It is a type of internal combustion engine based on the four-stroke engine, but with additional complexity intended to make it more efficient and reduce emissions. Two types of six-stroke engine have been developed since the 1990s.

In the first approach, the engine captures the heat lost from the four-stroke Otto cycle or Diesel cycle and uses it to power an additional power and exhaust stroke of the piston in the same cylinder. Designs use either steam or air as the working fluid for the additional power stroke. The pistons in this type of six-stroke engine go up and down three times for each injection of fuel. There are two power strokes: one with fuel, the other with steam or air.

The second approach to the six-stroke engine uses a second opposed piston in each cylinder that moves at half the cyclical rate of the main piston, thus giving six piston movements per cycle. Functionally, the second piston replaces the valve mechanism of a conventional engine but also increases the compression ratio.

The strokes are depicted as shown below.

piston ring

A piston ring is a split ring that fits into a

groove on the outer diameter of a piston in a reciprocating engine such

as an internal combustion engine or steam engine.

The three main functions of piston rings in reciprocating engines are :

>Sealing the combustion chamber so that there is no transfer of gases from the combustion chamber to the crank.

>Supporting heat transfer from the piston to the cylinder wall.

Regulating engine oil consumption.

>The gap in the piston ring compresses to a few thousandths of an inch when inside the cylinder bore.

The three main functions of piston rings in reciprocating engines are :

>Sealing the combustion chamber so that there is no transfer of gases from the combustion chamber to the crank.

>Supporting heat transfer from the piston to the cylinder wall.

Regulating engine oil consumption.

>The gap in the piston ring compresses to a few thousandths of an inch when inside the cylinder bore.

Suspension spring

Suspension spring

..........................

A suspension spring serves two purposes. It acts as a buffer between the suspension and frame to absorb vertical wheel and suspension movement without passing it on to the frame. Each spring transfers part of the vehicle weight to the suspension component it rests on, which transfers it to the wheels. All springs give way to absorb the vertical force of the moving wheel during jounce, then release that force during rebound as they return to their original shape and position. Leaf springs flatten, coil and air springs compress, and torsion bars twist.

Spring Materials

Most are made of a tempered steel alloy known as spring steel, usually chrome silicon or chrome-vanadium alloy. Tempering is controlled heating and cooling metal to increase the ability of the metal to return to, or spring back to, its original shape after being twisted or compressed.

..........................

A suspension spring serves two purposes. It acts as a buffer between the suspension and frame to absorb vertical wheel and suspension movement without passing it on to the frame. Each spring transfers part of the vehicle weight to the suspension component it rests on, which transfers it to the wheels. All springs give way to absorb the vertical force of the moving wheel during jounce, then release that force during rebound as they return to their original shape and position. Leaf springs flatten, coil and air springs compress, and torsion bars twist.

Spring Materials

Most are made of a tempered steel alloy known as spring steel, usually chrome silicon or chrome-vanadium alloy. Tempering is controlled heating and cooling metal to increase the ability of the metal to return to, or spring back to, its original shape after being twisted or compressed.

Subscribe to:

Posts (Atom)

![Clutch, clutch, clutch types, explaining the clutchPart of Mahrrk parts carsClutch (Clutch)The main purpose of the clutch is reached and the separation of traffic between the engine and the Fund speeds. As he tool to transfer torque from the engine to fund speed gradually to allow the car to move in easily. As he works to separate the movement when changing - interleave - gears or when standing in the case stillness and the engine in motion. clutch is located between the engine and speeds Fund and زالك considered clutch (clutch) is very important in the car.For more join @[362500073782692:274:Mechanical Engineers Rocks.]](https://fbcdn-sphotos-g-a.akamaihd.net/hphotos-ak-ash3/1472783_682132021819494_1059285737_n.jpg)